DATASHEET

SMD ?B

59-146UTD/TR8

10

opyright ? 2010, Everlight All Rights Reserved. Release Date : 09-May-2013. Issue No: DSE-0008905 Rev.4

www.everlight.com

Precautions For Use

1. Over-current-proof

Customer must apply resistors for protection, otherwise slight voltage shift will cause big

current change ( Burn out will happen ).

2. Storage

2.1 Do not open moisture proof bag before the products are ready to use.

2.2 Before opening the package: The LEDs should be kept at 30 or less and 90%RH or less.

2.3 After opening the package: The LED's floor life is 1 year under 30 or less and 60% RH or less.

If unused LEDs remain, it should be stored in moisture proof packages.

2.4 If the moisture absorbent material (silica gel) has faded away or the LEDs have exceeded the

storage time, baking treatment should be performed using the following conditions.

Baking treatment : 60 5 for 24 hours.

3. Soldering Condition

3.1 Pb-free solder temperature profile

P r e - h e a t i n g

1 5 0 ~ 2 0 0 ?nbsp C

6 0 ~ 1 2 0 s e c .

A b o v e 2 1 7 ?nbsp C

6 0 ~ 1 5 0 s e c .

2 6 0 ?nbsp C M a x .

1 0 s e c . M a x .

6 ?nbsp C / s e c . M a x .

A b o v e 2 5 5 ?nbsp C

3 0 s e c . M a x .

3 ?nbsp C / s e c . M a x .

3.2 Reflow soldering should not be done more than two times.

3.3 When soldering, do not put stress on the LEDs during heating.

3.4 After soldering, do not warp the circuit board.

4.Soldering Iron

Each terminal is to go to the tip of soldering iron temperature less than 350 for 3 seconds within once in less than the

soldering iron capacity 25W. Leave two seconds and more intervals, and do soldering of each terminal. Be careful because

the damage of the product is often started at the time of the hand solder.

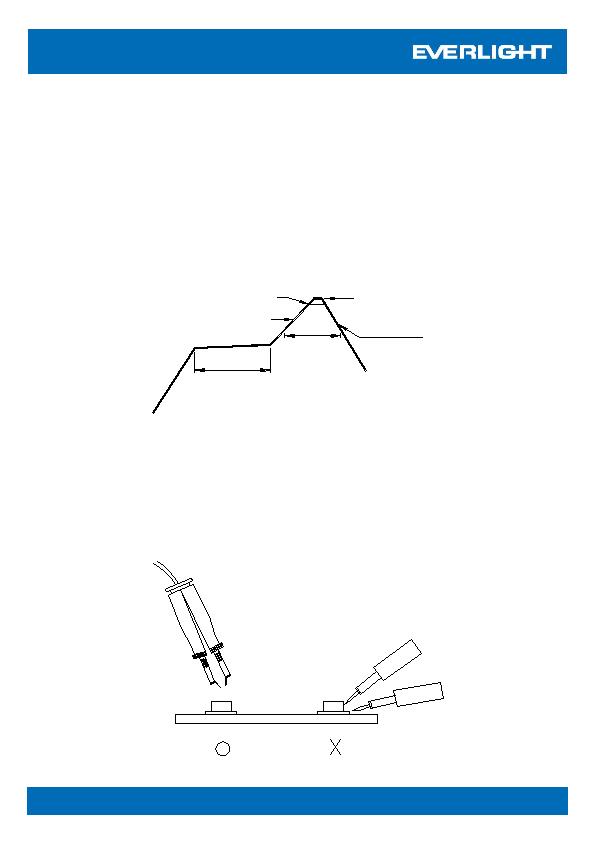

5.Repairing

Repair should not be done after the LEDs have been soldered. When repairing is unavoidable, a double-head soldering

iron should be used (as below figure). It should be confirmed beforehand whether the characteristics of the LEDs will or will

not be damaged by repairing.

发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

597-2301-202F

LED SIDELED GREEN 572NM SMD

597-2401-407

LED RIGHT ANGLE YELLOW SMT

597-2712-602F

LED RED/GRN/BLUE RT ANG 1208 SMD

597-2723-602F

LED GREEN 571NM RT ANG 1208 SMD

597-2901-821F

LED WHITE RT ANGLE 1616 SMD

597-3001-202F

LED RED 630NM 30MA 2-PLCC SMD

597-3001-207

LED RED SMT

597-3002-302F

LED RED ALLNGAP 630NM 2-PLCC SMD

相关代理商/技术参数

59-146UTD-TR8

制造商:EVERLIGHT 制造商全称:Everlight Electronics Co., Ltd 功能描述:Luminosity white Color LED

59-146UWD

制造商:EVERLIGHT 制造商全称:Everlight Electronics Co., Ltd 功能描述:Luminosity white Color LED

59-146UWD/TR8

制造商:EVERLIGHT 制造商全称:Everlight Electronics Co., Ltd 功能描述:Luminosity white Color LED

59-146UWD-TR8

制造商:EVERLIGHT 制造商全称:Everlight Electronics Co., Ltd 功能描述:Luminosity white Color LED

591491-000

制造商:TE Connectivity 功能描述:D-500-0255-214-1 制造商:TE Connectivity 功能描述:DATABUS HARNESSES - Bulk

591492N001

制造商:TE Connectivity 功能描述:Conn Triaxial 制造商:TE Connectivity 功能描述:D-621-1635CS324 - Bulk

59-14TR8

制造商:EVERLIGHT 制造商全称:Everlight Electronics Co., Ltd 功能描述:Technical Data Sheet Luminosity white Color LED

59-14UTD

制造商:EVERLIGHT 制造商全称:Everlight Electronics Co., Ltd 功能描述:Technical Data Sheet Luminosity white Color LED